Category:Building plumbing

Introduction:

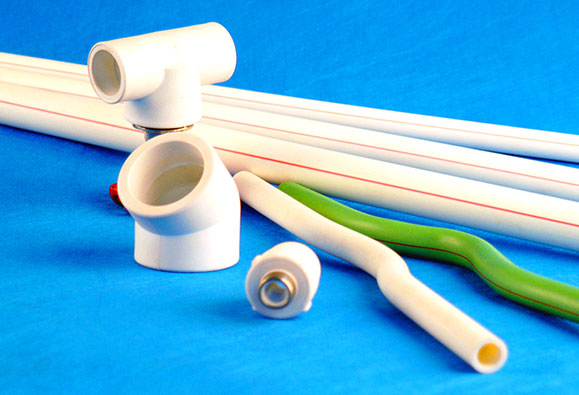

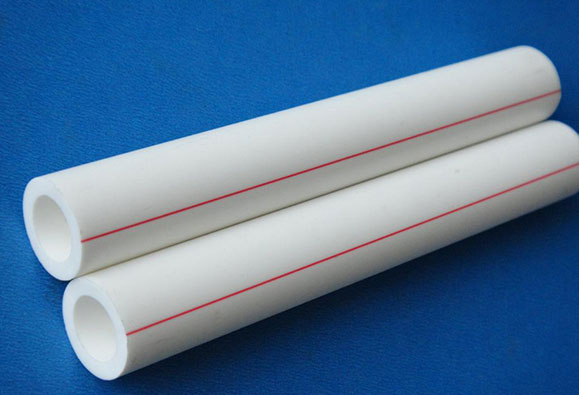

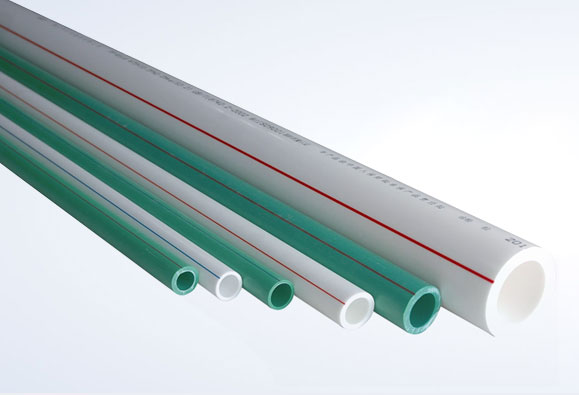

PP-R (random copolymerized polyethylene) is the third-generation polyethylene pipe exclusive material, also known as three-type polypropylene. It overcomes the shortcomings of homopolymer polyethylene and block copolymer polypropylene, and has both good impact resistance and long-term thermal properties, and has a longer service life under the same temperature and internal pressure conditions. It has been proved by experiments that the PP-R pipeline has a service life of 50 years under the condition that the internal pressure of 70℃ is 1Mpa, and it is a very ideal pipeline product.PP-R (random copolymerized polyethylene) is the third-generation polyethylene pipe exclusive material, also known as three-type polypropylene. It overcomes the shortcomings of homopolymer polyethylene and block copolymer polypropylene, and has both good impact resistance and long-term thermal properties, and has a longer service life under the same temperature and internal pressure conditions. It has been proved by experiments that the PP-R pipeline has a service life of 50 years under the condition that the internal pressure of 70℃ is 1Mpa, and it is a very ideal pipeline product.

Hebei Lile Pipe Co., Ltd. uses imported raw materials to process and produce PP-R pipes and pipe fittings. It has been inspected by the National Chemical Building Materials Testing Center and the Environmental and Health-related Product Safety Institute of the Chinese Center for Disease Control and Prevention. Product use and hygienic performance are better than national standards.

PP-R pipe fittings have the advantages of strong quality, good strength, corrosion resistance, no scaling and long service life in general plastic pipes, and also have the following main characteristics:

(1) It is hygienic and belongs to green building materials. The raw material of PP-R is polyolefin, and its molecule is composed of carbon and hydrogen elements, which is non-toxic and has reliable hygienic performance.

(2) It is heat-resistant, heat-insulating, and is an energy-saving product. The Vicat softening temperature of PP-R pipe is 131.3°C, the maximum service temperature is 95°C, and the long-term (50 years) service temperature can be as high as 70°C. The thermal conductivity of this product is 0.24W/m°C. It is only 1/200 of the thermal conductivity of steel pipes, and it has good thermal insulation and energy saving effects for hot water pipes.

(3) Easy and reliable installation, using hot-melt copper connection, a joint connection can be completed in a few seconds, and high-quality metal insert pipe fittings are used to connect with metal pipes and water appliances, which are reliable.

Project | Indicators | |

Pipe | Pipe fittings | |

Density g/cm3 | 0.9 | 0.9 |

Elastic Modulus MPa(20℃時) | 800 | 800 |

Thermal expansion coefficient mm/m·℃ | 0.15 | 0.15 |

Thermal conductivity W/m ℃ | 0.24 | 0.24 |

Vertical retraction% | ≤2 | - |

(Impact test) Damage rate% | Damage rate<10 | - |

Hydraulic test | No penetration | No penetration |

No penetration | No penetration | |

Hot melt connection method:

Cut pipe

When cutting the pipe, it must be cut vertically with a pipe cutter. If there is no pipe cutter, use other tools to cut the pipe. After cutting, the cutting head must be removed.

Heating Tubing and Tube Fittings

When the pipe fusion splicer is heated to 260°C, the pipe and pipe fittings are simultaneously pushed into the fusion splicer and heated for more than 5 seconds.

Connecting pipes and fittings

Push the heated pipe and pipe fittings vertically and hold for more than 5 seconds. Do not push too hard to prevent the pipe head from bending.

Notes on hot melt connection:

1. During hot-melt connection, when pipes and fittings adhere to other foreign objects, they must be cleaned and welded.

2. Push pipes and fittings into the fusion splicer mold with both hands.

3. When the pipes and fittings are overheated, the pipes will be deformed in the pipe fittings, and water leakage may occur. Remember to overheat.

1.Cold and hot water systems in buildings, including central heating systems

2.The building heating system, including floor, wainscoting material heating and radiation system

3.Direct drinking pure water supply system

4.Central (centralized) air-conditioning system

5.Agriculture, garden irrigation system

6.Swimming pool pipe network

7.Pipe network of solar facilities

Wechat QR code

Wechat QR code

Home

Home Tel

Tel Product

Product